Self-Lubricating: The pumped fuel itself lubricates the internal gears, reducing wear and extending service life.

5. Here are the key precautions for replacing a diesel engine fuel injection pump (or transfer pump), focusing on safety, correctness, and preventing damage.

1. Pre-Work Verification & Safety

Confirm the Failure: Diagnose thoroughly (check fuel pressure, filters, lines) before assuming the pump is faulty. Replacing an expensive pump unnecessarily is a major cost.

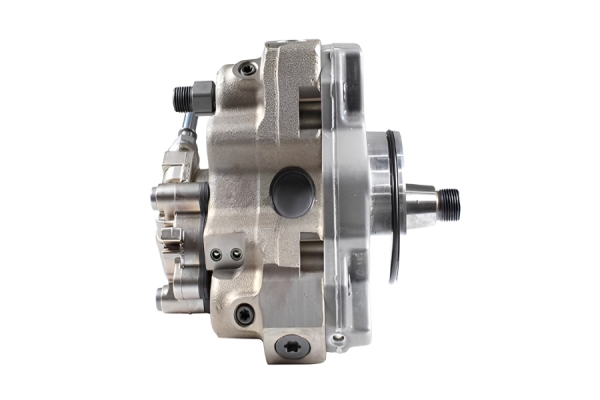

Use Correct Parts: Match the exact part number and specifications (e.g., 5594766) to your Engine Serial Number (ESN). Pumps for different calibrations or emissions standards are not interchangeable.

Safety First:

Disconnect the negative battery terminal.

Work in a well-ventilated area. Have a Class B fire extinguisher nearby.

Relieve fuel system pressure by slowly loosening connections. Catch spilled fuel.

Never smoke or create sparks near the work area.

2. Removal & Preparation

Cleanliness is Critical: Thoroughly clean the pump, its mounting flange, and the surrounding engine area with degreaser before disassembly. The smallest amount of dirt entering the fuel system or engine gear train can cause catastrophic failure.

Mark All Timing and Alignment Marks:

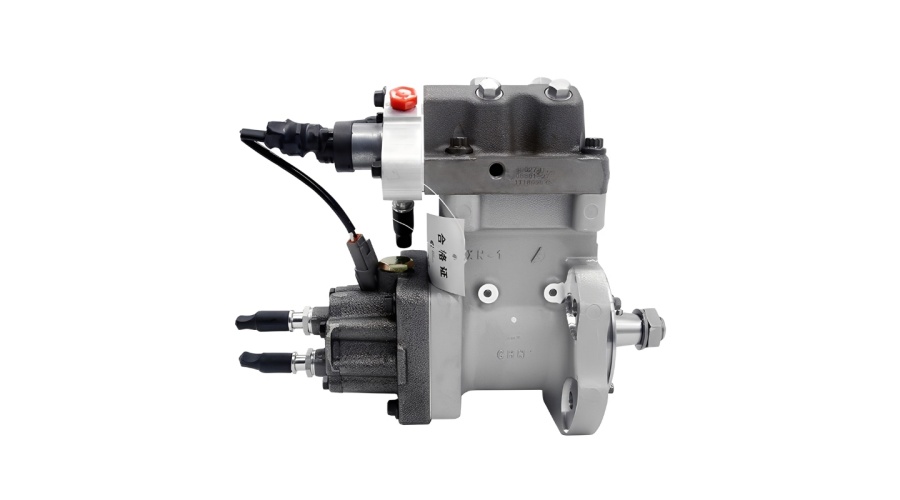

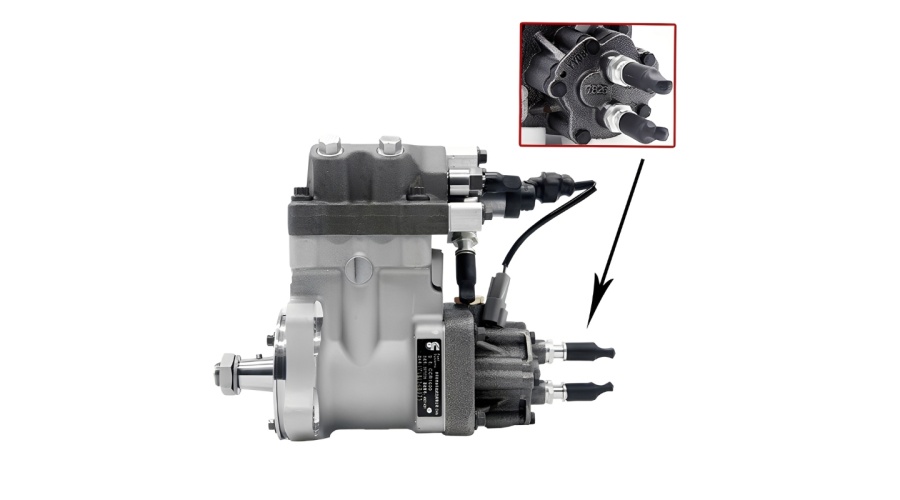

For gear-driven pumps, clearly mark the relationship between the pump drive gear and its mating gear, as well as the engine timing marks (on the front gear cover). If no marks exist, create your own with paint or a punch before disassembly. This is the single most important step to prevent engine timing errors.

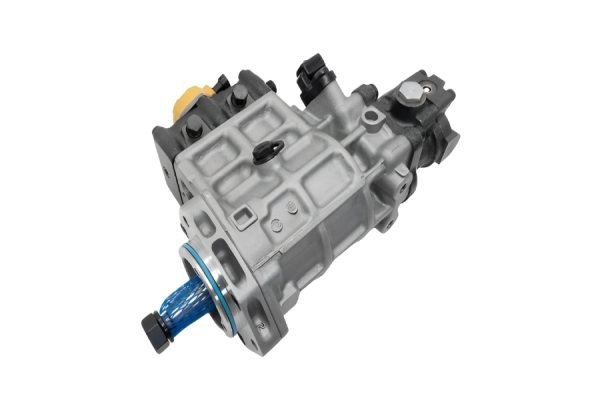

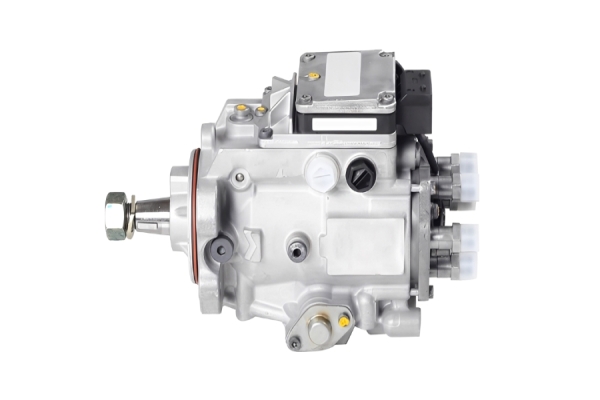

For pumps with flange-mounted sprockets (common rail), you must lock the engine at Top Dead Center (TDC) using official tools.

Label All Connections: Tag all fuel lines, electrical connectors, and sensors with tape to ensure correct reassembly.

3. Installation

Use New Seals & Gaskets: Always install a complete new seal kit, mounting gasket, and O-rings. Do not reuse old seals.

Lubricate: Lightly coat new seals and O-rings with clean diesel fuel or the specified assembly lubricant before installation.

Pre-fill the Pump: If possible, fill the new pump's inlet chamber with clean diesel to prevent a dry start, which can damage internal components.

Precision Timing Alignment: This is non-negotiable.

Carefully align the marked gears or use the official timing pins/tools as specified in the service manual.

For pumps driven by a timing belt, follow the exact procedure for belt tension and alignment. An incorrectly timed pump will cause poor running or severe engine damage.

Torque to Spec: Use a torque wrench to tighten mounting bolts and line fittings to the manufacturer's specifications in the correct sequence. Over-tightening can crack housings; under-tightening causes leaks.

Replace Associated Parts: It is highly recommended to install new primary and secondary fuel filters. If the old pump failed, metal debris may be in the system; consider flushing fuel lines and checking the tank for contamination.

4. Post-Installation & Priming

Prime the System: After installation, you must prime the entire fuel system to remove air. This typically involves:

Filling the new filters with clean fuel.

Using a manual primer pump (if equipped) or loosening bleed screws on the secondary filter and injection pump, then pumping until bubble-free fuel flows.

Do not crank the starter excessively to prime; this can damage an unlubricated pump.

Initial Start & Check:

After priming, reconnect the battery.

Crank the engine in short bursts (10-15 seconds) until it starts. It may run roughly initially as remaining air is purged.

Immediately check for fuel leaks at all connections.

Let the engine idle, then check for smooth operation and normal fuel pressure.

Test Drive & Final Check: Perform a test run, checking for power, smooth acceleration, and no leaks. Re-torque mounting bolts after the first heat cycle (cool down) if specified in the manual.

Critical Professional Advice

Technical Data is Essential: Always consult the official Service Manual (SIS) for your specific engine model. The procedure and torque specs are critical.

Consider the Root Cause: Ask why the pump failed. Was it due to contaminated fuel, a restricted inlet line, or a failing lift pump? Address the underlying issue to prevent rapid repeat failure.

Complexity Warning: Replacing a modern common rail high-pressure pump or a precisely timed mechanical pump is a high-skill task. An error in timing or installation can lead to instant, total engine destruction (e.g., bent valves, piston/valve contact). If you are not fully confident and equipped, entrust this job to a qualified diesel technician.