The number A4710900850 is a Bosch part number for a fuel injection pump, and it's famously associated with Detroit Diesel 6V92 and 8V92 two-stroke cycle diesel engines.

Here’s a detailed breakdown of what this part is and its context:

1. What is this Pump?

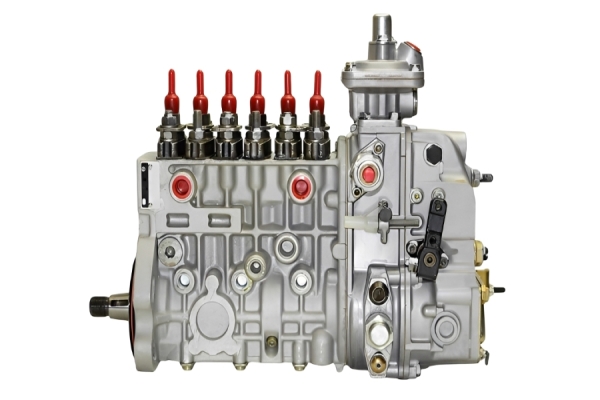

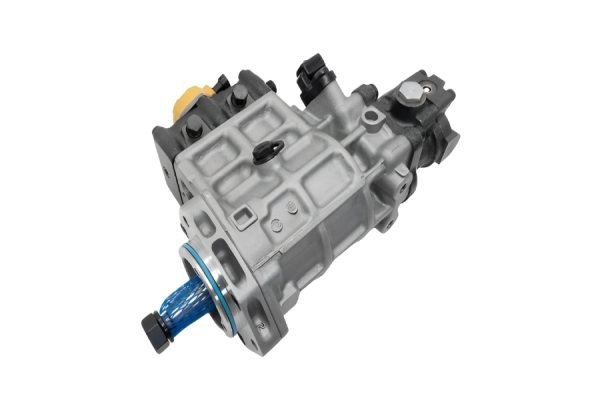

This is a Bosch PE-Series "P" type in-line fuel injection pump. It is a mechanically governed, multi-plunger pump that delivers high-pressure fuel to each cylinder in a precise firing order. For the Detroit 6V92 and 8V92 engines, it is a critical component that controls power, timing, and fuel efficiency.

2. Primary Application

Engine: Detroit Diesel 6V92 (6-cylinder) and 8V92 (8-cylinder) engines.

Configuration: The "V92" series are V-block, two-stroke diesel engines that were widely used from the 1970s through the 1990s.

Common Uses:

Heavy-Duty Trucks (e.g., Kenworth, Peterbilt, Freightliner)

Coaches and Intercity Buses (Greyhound, MCI)

Marine Engines (workboats, yachts)

Industrial and Generator Sets

3. Key Features & Function

In-Line Design: Has a separate plunger for each cylinder, all housed in a single unit.

Mechanical Governor: Integrated into the pump to control the engine's maximum speed (RPM) and low-speed operation.

Hydraulic Timing Advance: Automatically adjusts the injection timing based on engine speed for optimal performance and emissions.

Air-Fuel Ratio (AFR) Control: A unique Detroit Diesel feature that limits fuel delivery based on intake manifold boost pressure to prevent excessive smoke.

The Bosch PE-Series "P" pump (A4710900850) is a masterpiece of mechanical engineering, designed to meet the unique demands of the Detroit Diesel two-stroke cycle. Its structural features directly translate to distinct performance advantages.

Here’s a breakdown of its key structural features and the performance advantages they confer

I. Key Structural Features

1. In-Line, Multi-Plunger Design

Structure: A single, rigid aluminum housing contains a vertical bank of individual plungers (6 or 8), one for each engine cylinder. Each plunger is actuated by a central camshaft running the length of the pump.

Implication: This provides a simple, robust, and modular layout where each cylinder's fuel delivery is controlled by its own dedicated high-pressure element.

2. Helix-Controlled Plungers (Spill-Port Metering)

Structure: Each plunger has a precision-machined vertical groove and helix (spiral) on its side. Rotating the plunger (via the governor and control rack) changes the relationship between the helix edge and a spill port in the barrel. This controls when during the plunger's upward stroke fuel delivery is cut off.

Implication: This is the heart of the metering system. The degree of plunger rotation determines the effective stroke and thus the volume of fuel delivered per injection.

3. Integral Mechanical Governor

Structure: Mounted directly to the rear of the pump housing. It consists of rotating flyweights driven by the pump camshaft, a speeder spring, and a complex linkage connected to the fuel control rack.

Implication: This is a self-contained speed-regulation system. It automatically adjusts the fuel rack position based on engine load and operator demand (throttle position) to maintain a set RPM.

4. Hydraulic Timing Advance Unit

Structure: Located at the front (drive end) of the pump. It’s a piston-and-spring mechanism that uses engine oil pressure (from the engine's lubrication system) to rotate the internal camshaft relative to the pump drive gear.

Implication: This allows for dynamic injection timing adjustment. As engine speed (and oil pressure) increases, the timing is automatically advanced.

5. Air-Fuel Ratio (AFR) Control / Aneroid

Structure (Critical for Detroit 2-Strokes): A boost-pressure-sensitive diaphragm housing mounted on top of the pump. It is connected to the engine's intake manifold. Internally, it mechanically limits the full-travel of the fuel control rack.

Implication: This device directly links fuel delivery to available intake air (boost). It prevents the pump from delivering maximum fuel at low boost, which would cause excessive smoke. Only at full boost can the rack move to its full-fuel position.

6. Constant-Stroke Design

Structure: The camshaft and follower give each plunger a fixed physical stroke. The amount of fuel delivered is varied not by changing the stroke length, but by cutting off delivery early via the helix/spill port.

Implication: This simplifies mechanics and allows for very high, consistent injection pressures regardless of delivery volume.

II. Performance Advantages

1. Exceptional Durability & Simplicity

Advantage: The all-mechanical, gear-driven design has no electronics vulnerable to heat, vibration, or moisture. Its robust construction, with lubricating diesel fuel itself, gives it an extremely long service life (often 500,000+ miles) and makes it rebuildable multiple times.

2. Precise, Individual Cylinder Fueling

Advantage: Each cylinder has its own dedicated plunger and barrel. Skilled technicians can "balance" the pump by minutely adjusting individual plunger deliveries on a test bench. This ensures perfectly even power contribution from all cylinders, leading to smoother operation, better fuel economy, and lower engine stress.

3. Self-Optimizing Timing (Hydraulic Advance)

Advantage: The timing advance unit provides optimal combustion across the RPM range.

At low RPM: Timing is retarded, improving cold starts, reducing noise, and preventing excessive cylinder pressure.

At high RPM: Timing is advanced, allowing more time for complete combustion, which improves power, efficiency, and reduces exhaust temperature.

4. Built-In Smoke & Over-Speed Protection

Advantage: This is where the Detroit application shines.

AFR Control: This mechanical "smoke limiter" is brutally effective. It makes the iconic 92-series engines surprisingly clean-smoking for their era under acceleration and load.

Mechanical Governor: It provides absolute, failsafe protection against engine "runaway" or destructive over-speeding, a critical safety feature.

5. High Injection Pressure & Good Atomization

Advantage: The constant-stroke design, with strong cam profiles, generates very high line pressures (upwards of 5,000 - 7,000+ psi at the pump outlet). This, combined with the pencil-type injectors on the Detroit, creates excellent fuel atomization for more efficient and cleaner combustion.

6. Predictable, "Tunable" Performance

Advantage: For enthusiasts and operators, the mechanical nature is an advantage. Performance can be predictably modified by:

Changing plunger size ("fuel head").

Adjusting the governor springs and weights.

Modifying the AFR control spring.

Altering the timing advance rate.

This allowed these engines to be tailored for specific needs (e.g., high-horsepower trucking vs. high-torque marine use).

Conclusion:

The structural features of the Bosch A4710900850 pump create a system of robust, mechanical interdependence. Its advantages are durability, precise mechanical control, built-in safety logic (governor + AFR), and tunability. It was the perfect "brain" for the Detroit 6V92/8V92—an engine that demanded precise, high-pressure fueling matched perfectly to its two-stroke, supercharged scavenging cycle. It represents the peak of pre-computer diesel injection technology

Where to buy:

Rsolid is a professional manufacturer of diesel engine system components, providing high-quality and durable engine parts for different brands of engines, or producing fuel injectors and diesel pumps according to your requirements. The company is positioned as a professional and excellent supplier of automotive parts for foreign trade, including high-quality fuel injectors and diesel pumps. With years of international market experience, Rsolid has become a reliable partner for global customers seeking authentic Detroit products and comprehensive value-added services. The company is firmly committed to quality assurance, typically supported by international certifications commonly found in the automotive parts industry, ensuring that all parts undergo rigorous flow, pressure resistance, and leak integrity testing before being sold. Rsolid's business model typically includes maintaining a diverse and comprehensive inventory of OEM and high-end aftermarket parts, and offering cross compatible options to meet a wide range of applications and global customers from individual workshops to large fleet operators. If you are looking for diesel injectors or OEM engine diesel pumps, please feel free to contact us at any time .