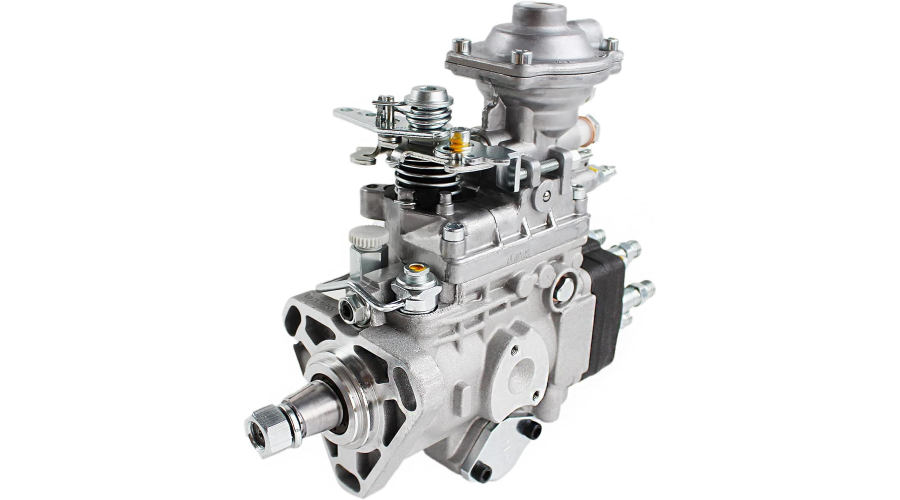

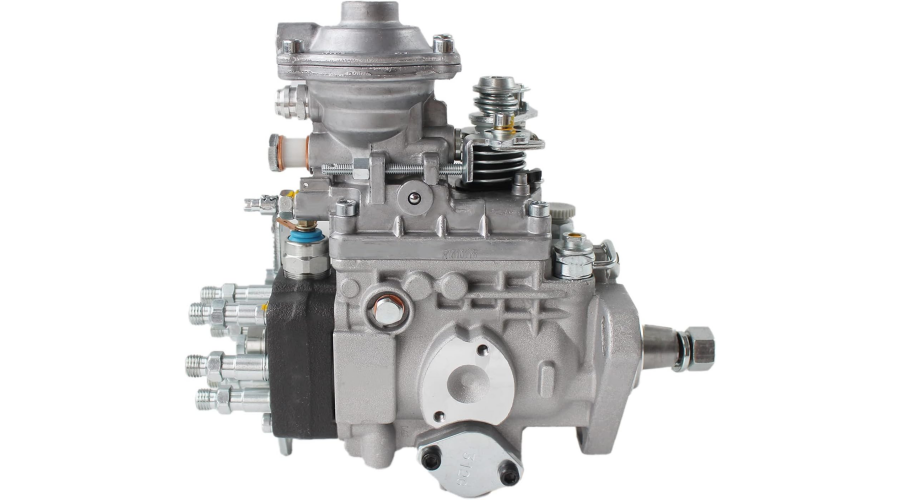

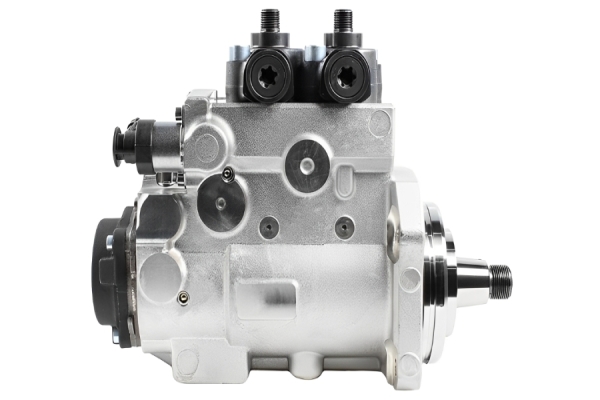

Type: Mechanical Rotary Distributor Pump. It is driven by the engine's gear train and uses internal mechanical components (a rotating plunger) to meter and distribute fuel to each injector in the correct firing order.

Fuel System: It is the heart of the fully mechanical fuel system on the 12-valve 5.9L. This means engine timing and fuel delivery are controlled by the pump's internal mechanics and a mechanical governor, not by a full-authority Engine Control Module (ECM). This is a key reason for its legendary reputation for simplicity and reliability.

Components on the Pump: The 3916991 typically incorporates:

Fuel Transfer Pump: Draws fuel from the tank.

Mechanical Governor: Controls engine RPM.

Advance Mechanism: Adjusts injection timing based on engine speed.

Cold Start Solenoid: Advances timing for easier cold starts.

Fuel Shut-Off Solenoid: Cuts fuel to stop the engine.

1. Structural Characteristics and Advantages of the Bosch VE Pump (3916991)

The Bosch VE (Verteiler-Einspritzpumpe) is a masterpiece of mechanical engineering. Its design is integral to the legendary status of the 12-valve 5.9L Cummins.

Structural Characteristics:

Single Plunger & Distributor Head Design: This is the core innovation. Unlike inline pumps with a plunger for each cylinder, the VE pump uses one single high-pressure plunger that reciprocates (pumps) and rotates (distributes).

The plunger's stroke creates the high pressure.

Its rotation aligns with ports in the distributor head to sequentially deliver fuel to each of the six injector lines in the correct firing order. This design drastically reduces size, weight, and complexity.

Integrated Components (All-in-One Unit):

Vane-Type Transfer Pump: Mounted on the back, it pulls fuel from the tank and supplies it to the high-pressure side.

Mechanical Centrifugal Governor: Uses rotating flyweights to sense engine RPM and mechanically adjust the plunger's stroke (fuel delivery) to maintain a set speed. It's responsible for the iconic "jake brake" sound when decelerating.

Hydraulic Timing Advance: Uses engine oil pressure to rotate the internal cam ring, advancing injection timing as RPM increases for optimal efficiency and power.

Fuel Control Solenoid (LDA): While the engine is mechanically controlled, this solenoid (often called the "boost compensator") adjusts fuel based on intake manifold pressure (boost). More boost = allows more fuel, improving turbo response and reducing smoke.

Gear-Driven & Self-Lubricating: It is directly gear-driven from the engine's timing gear train, ensuring precise synchronization with the crankshaft. It is lubricated by the engine's diesel fuel, not engine oil.

Key Advantages:

Legendary Simplicity & Reliability: With no reliance on complex electronics (pre-ECM), it has fewer catastrophic failure points. Its operation is purely mechanical and predictable.

Compact & Lightweight: The single-plunger design makes it much smaller and lighter than an equivalent inline pump (like those on larger Detroit Diesels), simplifying installation and packaging.

Excellent Fuel Economy: When properly calibrated and timed, its mechanical efficiency is superb, a major reason for the 12-valve's reputation for fuel economy.

Tunability & Mechanical Character: Enthusiasts and mechanics can adjust power output (within limits) by changing springs, adjusting the fuel screw, or modifying the governor. Its direct mechanical response is prized by purists.

Robustness: The design is inherently durable and can tolerate a wider range of fuel conditions (within reason) compared to modern ultra-high-pressure electronic pumps.

2. Main Symptoms of Failure & Critical Replacement Precautions

Main Symptoms of Diesel Pump Failure:

Symptoms often start subtle and become severe.

Starting Problems:

Long Cranking / Hard to Start: Worn plunger/head cannot build sufficient pressure.

No Start: Complete failure of the transfer pump, seized plunger, or a failed fuel shut-off solenoid (you may not hear its distinct "click" when turning the key on).

Performance Issues:

Significant Loss of Power & "Flat Spot": The pump cannot deliver the required volume of fuel under load. The engine feels gutless and won't accelerate.

Unstable/Rough Idle or Surging RPM: Governor mechanism is worn or sticking, unable to regulate idle speed properly.

Smoke & Combustion Issues:

Excessive Black Smoke: Caused by over-fueling due to a stuck metering sleeve or incorrect calibration.

Excessive White or Blue Smoke: Often due to severely retarded timing caused by a failed timing advance mechanism, leading to incomplete combustion.

Operational Abnormalities:

Fuel Leaks: Visible leaks from the pump housing, shaft seal (front), or throttle shaft seals. The pump's internal fuel lubrication means a leak also means internal wear.

Knocking or "Pinging" Noise: Excessively advanced timing (often from a stuck advance piston) causes a sharp, damaging metallic knock.

High Idle or Runaway Engine (RARE but SERIOUS): A catastrophic governor failure or throttle linkage issue can prevent the pump from reducing fuel, causing the engine to overspeed. Know your emergency shutdown procedure.

Precautions When Replacing the Pump (A Step-by-Step Guide):

Replacing this pump is a major job. Mistakes are costly.

A. Before Removal & When Ordering:

RECORD THE CALIBRATION NUMBER: This is the most important step. Find the 4-digit code (e.g., 6083) on the pump tag. Your new/remanufactured pump MUST be calibrated to this exact number for your specific engine/vehicle application.

Buy Quality: Invest in a remanufactured pump from a reputable diesel shop, not an unknown online seller. They will properly rebuild, calibrate, and test it.

Order a Complete Kit: Purchase a replacement pump install kit. This should include:

New fuel inlet and return line seals (O-rings/sealing washers).

New front crankshaft seal (while you have access).

New injection pump gear bolts (they are often torque-to-yield and must be replaced).

New fuel filter(s).

Cleanliness is Godliness: Clean the engine bay, especially around the pump and fuel lines, before starting. Have plenty of clean, lint-free rags on hand.

B. During Installation:

Prime the Pump: Before installing, fill the pump's fuel inlet port with clean, filtered diesel fuel or clean engine oil. A dry start can instantly damage the internal plunger and head.

Set Engine to Top Dead Center (TDC): Follow the service manual procedure exactly. Usually, you align marks on the vibration damper and the timing case cover, and confirm the #1 cylinder is on its compression stroke.

Time the Pump Gear: The pump gear must be meshed with the idler gear in the correct orientation. There is a specific timing mark (often a dot or line) on the gear that must align with a mark on the idler gear or block. Do not guess. Use the factory procedure.

Set Pump Static Timing: After the pump is bolted down but before the gear is bolted to the pump shaft, you must set the pump's internal position using a dial indicator in the pump's timing port. This step is NON-NEGOTIABLE for correct operation and longevity.

Torque Correctly: Use a torque wrench for all critical fasteners, especially the pump mounting bolts and the pump gear bolts. Over- or under-torquing can cause leaks or catastrophic failure.

Bleed the Air: After installation, bleed all air from the fuel system. Loosen the inlet banjo bolt at the pump to prime the transfer pump, then crack open the injection line nuts at the injectors (one by one) while cranking until solid fuel squirts out.

C. Final Checks:

Check for Leaks: Before and after starting, inspect all connections meticulously.

Verify Timing with a Meter (Optional but Recommended): Using a diesel timing meter (like a Snap-on MT3101) that reads off the #1 injector line will confirm the dynamic timing is within specification after startup.

Test Drive & Monitor: Perform a gentle test drive, checking for smooth power delivery, proper idle, and no excessive smoke.

3916991 Diesel Injection Pump Supplier:

Rsolid is a professional manufacturer of diesel engine system components, providing high-quality and durable engine parts for different brands of engines, or producing fuel injectors and diesel pumps according to your requirements. The company is positioned as a professional and excellent supplier of automotive parts for foreign trade, including high-quality fuel injectors and diesel pumps. With years of international market experience, Rsolid has become a reliable partner for global customers seeking authentic OEM products and comprehensive value-added services. The company is firmly committed to quality assurance, typically supported by international certifications commonly found in the automotive parts industry, ensuring that all parts undergo rigorous flow, pressure resistance, and leak integrity testing before being sold. Rsolid's business model typically includes maintaining a diverse and comprehensive inventory of OEM and high-end aftermarket parts, and offering cross compatible options to meet a wide range of applications and global customers from individual workshops to large fleet operators. If you are looking for diesel injectors or OEM engine diesel pumps, please feel free to contact us at any time .