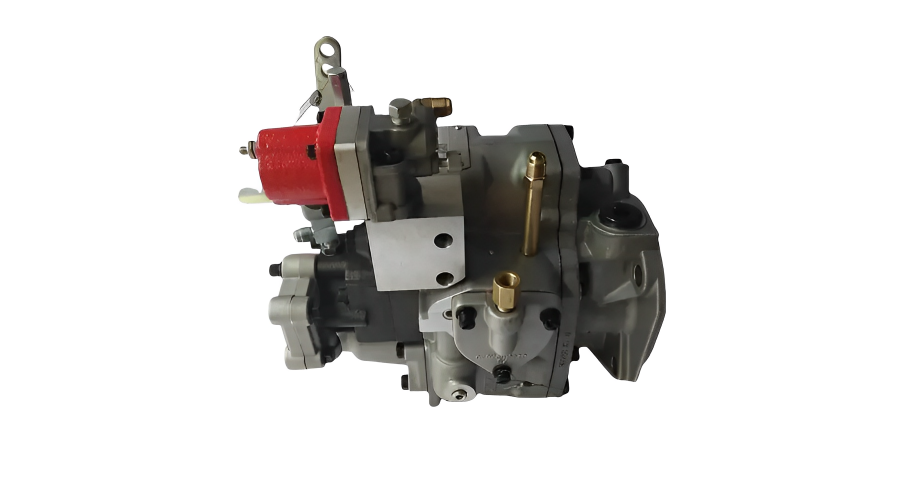

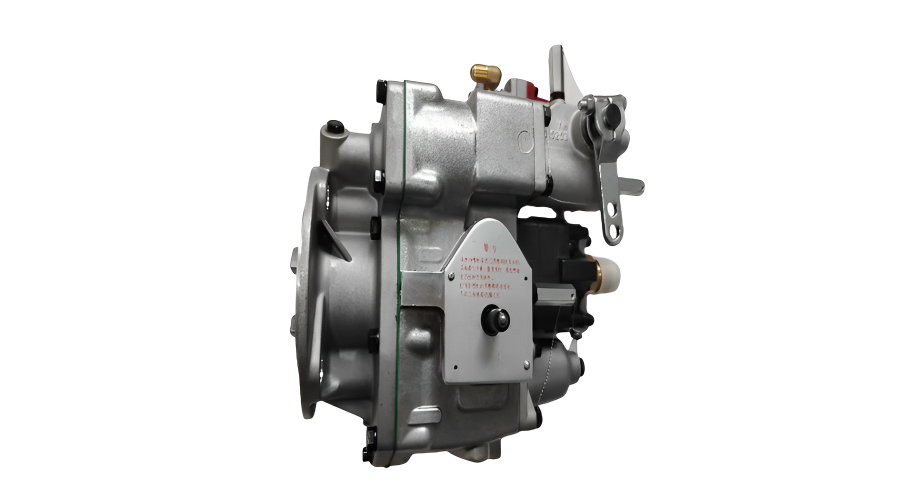

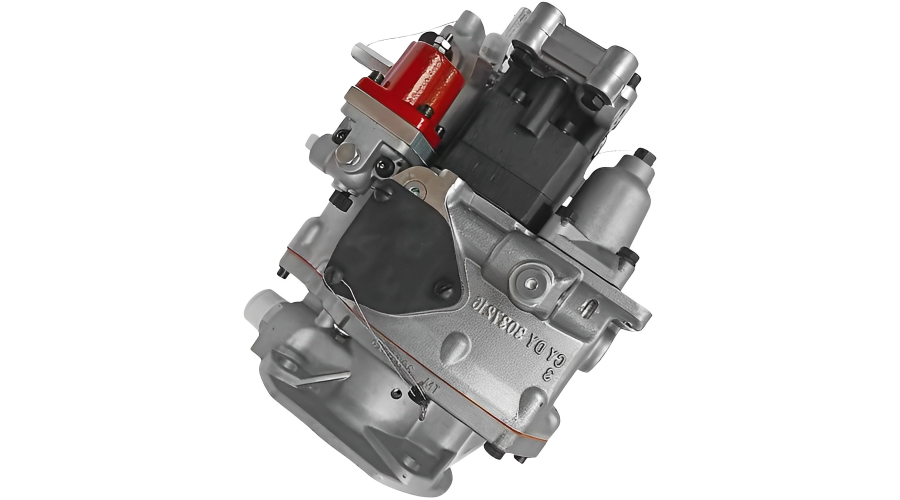

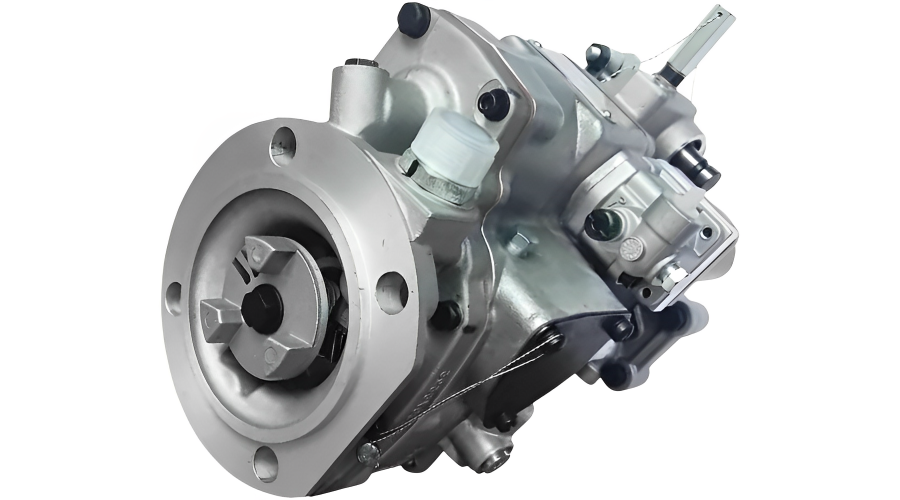

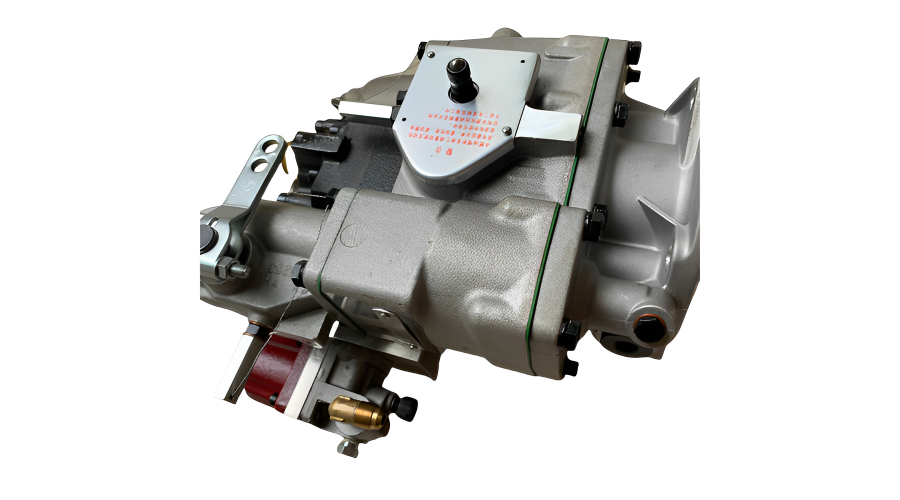

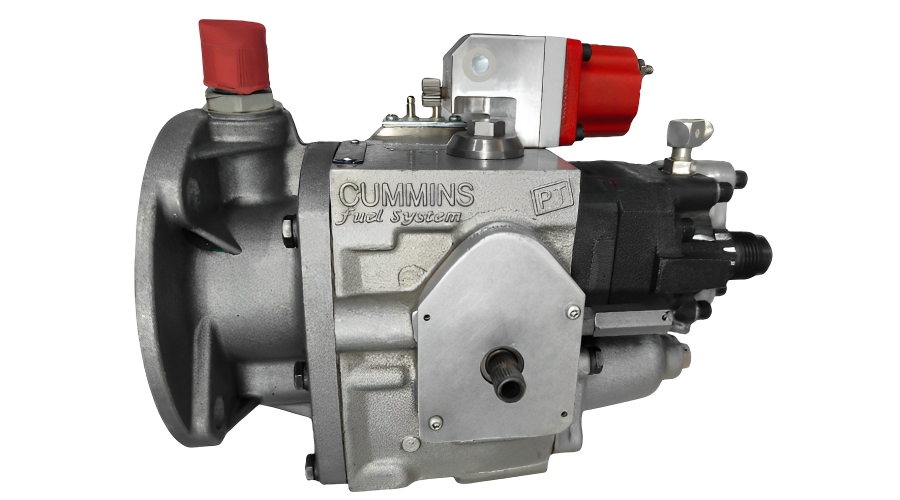

Fuel Injection Pump 4061206 3021961 Compatible with Cummins Engine K19 KTA19 KTA19-GC NT855

The diesel pump of an engine usually refers to one of the core components in the fuel system of a diesel engine, mainly responsible for delivering diesel from the fuel tank and delivering it to the injector under extremely high pressure for injection into the cylinder for combustion.

Its more accurate name is usually "high-pressure fuel pump" or "fuel injection pump". This is a key component that distinguishes diesel engines from gasoline engines, as diesel needs to be compressed to very high pressures to achieve good atomization and combustion.

The following is key information about diesel pumps (high-pressure fuel pumps):

1. Main functions:

*Fuel supply: Draw fuel from the fuel tank (through a low-pressure fuel transfer pump).

*Pressurization: Raise the fuel pressure to the extremely high pressure required for fuel injection (usually ranging from a few hundred Bar to over 2000 Bar).

*Measurement: Accurately control the amount of fuel injected into the cylinder each time according to the instructions of the engine control unit (ECU) (electronic control system).

*Timing: High pressure fuel is delivered to the injector at precise times to ensure that fuel is injected at the correct piston position (traditional mechanical pumps are controlled by camshaft phase, while electronic control pumps are controlled by ECU).

*Distribution: (For distribution pumps) Distribute high-pressure fuel to the injectors of each cylinder in the order of ignition.

2. Type:

*In line pump: It is common in old diesel engines, with each cylinder corresponding to a plunger sleeve component. The structure is sturdy and durable, but it has a large volume, heavy weight, and relatively inflexible control.

*Distribution pump: Only one or a few high-pressure pump oil components distribute high-pressure oil to each cylinder injector in sequence through a rotating distributor. Small in size and light in weight, it has been widely used in small and medium-sized diesel vehicles, but its high-pressure capacity is relatively limited.

*Single unit pump: Each cylinder is equipped with a small high-pressure pump (pump nozzle or single unit pump), usually installed on the cylinder head. Directly driven by the camshaft, it can generate extremely high fuel injection pressure, with good performance but complex structure.

*Common rail system: the most mainstream system in modern diesel engines. The core is a "high-pressure fuel pump" that continuously pumps fuel into a common accumulator pipe (common rail pipe). Always maintain a very high constant pressure inside the track (up to 2000Bar or more). ECU achieves precise and flexible control of fuel injection quantity, timing, and pattern by controlling the opening time and frequency of high-speed solenoid valves or piezoelectric crystal valves on each injector. The structure of the high-pressure oil pump itself is relatively simple, mainly responsible for establishing and maintaining rail pressure.

3. Importance:

*The performance and reliability of diesel pumps are directly related to the power output, fuel economy, emission level, noise and smoothness of the engine.

*It is one of the components with the highest technical content and the most stringent manufacturing accuracy requirements in the fuel system of diesel engines.

4. Maintenance and upkeep:

*Using qualified and clean diesel: This is the most critical factor in protecting high-pressure fuel pumps! Poor quality diesel, moisture, and impurities can severely wear down precision components.

*Regularly replace the fuel filter: strictly follow the maintenance manual requirements to replace it, which is the last line of defense to prevent impurities from entering the high-pressure pump.

*Avoid prolonged low fuel operation: prevent impurities from being sucked into the bottom of the fuel tank, while ensuring the cooling and lubrication of the fuel pump (the fuel itself has a lubricating effect).

*Regular inspection: Pay attention to any signs of fuel leakage (external or internal leakage into the engine oil).

*Professional maintenance: The high-pressure oil pump has a precise structure, and maintenance and debugging require professional equipment and technical personnel. Non professionals are not allowed to disassemble at will.

In summary, the "diesel pump of an engine" mainly refers to the high-pressure fuel pump (fuel injection pump) in the fuel system of a diesel engine. It is one of the "hearts" of diesel engines, responsible for generating extremely high fuel pressure and precisely controlling fuel supply, which is crucial to engine performance. Modern diesel engines commonly use a common rail system, where the high-pressure fuel pump continuously provides high-pressure fuel to the common rail pipe. Maintaining fuel cleanliness and regularly replacing filters are key to extending their lifespan. If a diesel pump malfunction is suspected, professional diagnosis and repair should be sought.