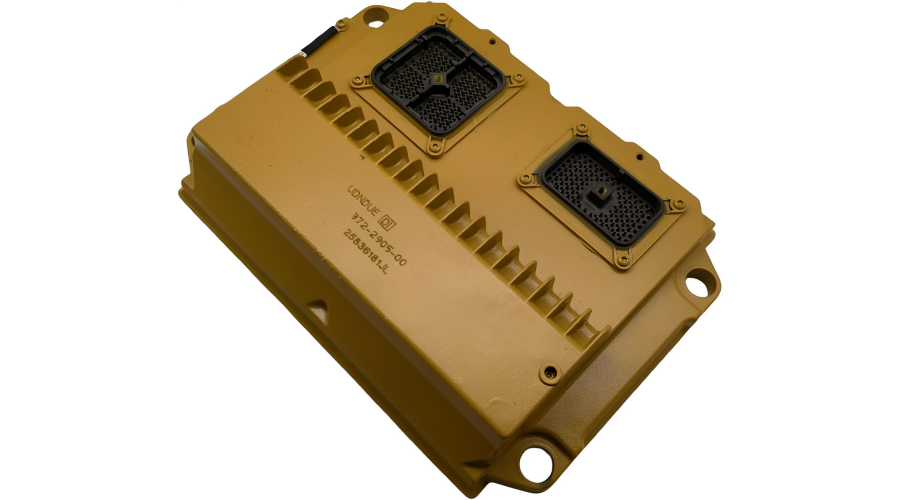

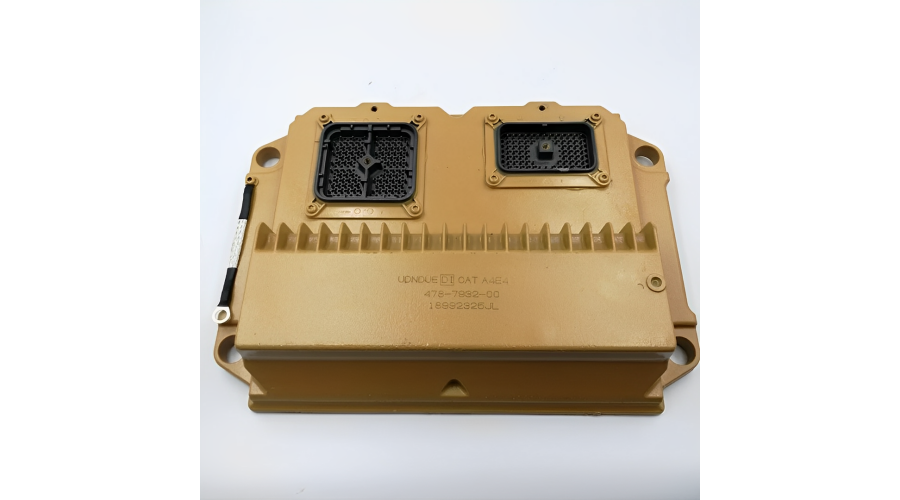

Hot selling ECM models:

20R-5038 ,20R8825 ,20R8220,20R-6471,20R8192,10R-5645,20R8190 ,348-2390,172-9387,3709478,

569-8638,285-1133,512-5720 20r-2320, 592-5153, 20R-1766, 20R1834, 20R-6112, 20R-3745, 20R-8183, 20R-6911,

20R-8188, 20R-5037,20R-887

The replacement of the original ECM must strictly follow the Caterpillar repair specifications,

otherwise it may damage the engine:

1. * * Backup the original ECM parameters**

-Using Cat ® ET (Electronic Technician) prints configuration parameters and records the injector serial number

and calibration code (must be reprogrammed after replacing the injector or ECM).

2. * * Copy the configuration to the new ECM**

-Select 'Copy Configuration/ECM Replacement' → 'Load from ECM' → 'Program ECM' through ET. If it fails,

manual input of parameters is required (some parameters need to be obtained from the factory).

3. * * Precautions for Hardware Replacement**

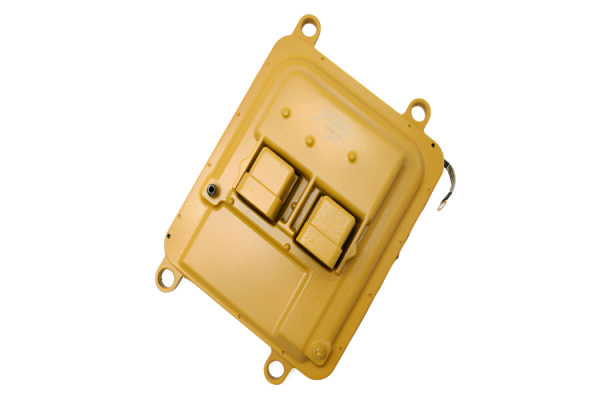

-Disconnect the power supply and J1/P1, J2/P2 connectors;

-Ensure that the grounding strap is securely installed to avoid poor contact caused by vibration;

-The fuel pipeline needs to reserve buffer space to prevent pulling the ECM.

4. * * Software and Calibration**

-Install the latest flash file (version errors can cause engine damage);

-Calibrate the fuel injection timing and check for diagnostic codes

(such as CID 0600 hydraulic oil temperature sensor abnormality).

---

### ⚠ ** 4、 Usage and maintenance suggestions**

1. * * Regular diagnosis**

-Using Cat ® ET or Messenger reads the fault code (such as CID 0246 CAN bus abnormality for MID 082) and

promptly cleans the sensor dirt.

2. Environmental and oil requirements**

-Use clean diesel with a filtration accuracy of ≤ 5 μ m to prevent clogging of precision components;

-The working temperature should be ≤ 26 ℃ to avoid ECM component aging caused by high temperature.

3. * * Preventive maintenance**

-Calibrate rail pressure sensors and flow meters every six months;

-Check the waterproof sealing of the wiring harness, especially in high humidity environments such as mines

and ships.

4. * * Fault response**

-Symptoms of ECM failure: sudden power drop, shaking and stalling, black smoke emission.

-Emergency plan: Immediately shut down the machine, check the power supply and grounding;