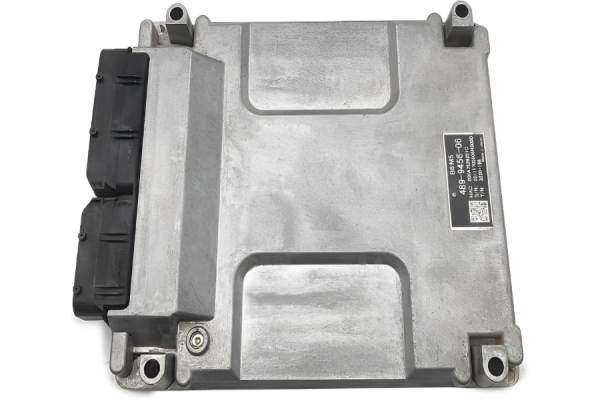

Here is a detailed overview of the CM871 (ECM Serial Number 3684275), the Engine Control Module for the Cummins QSB Series, focusing on its control and interface.

ECM CM871 - Core Information

The CM871 is a full-authority, digital electronic control module that governs the fuel system, air handling, and overall operation of QSB-series diesel engines (common in industrial, generator, and marine applications). Your specific ECM serial number (3684275) is unique for service and programming purposes.

There is NO Physical "Control Panel"

This ECM does not have a standalone control panel with buttons and a screen. Instead, control, monitoring, and diagnostics are performed through external interfaces:

1. Primary Service & Diagnostic Tool: Cummins INSITE™

This is the official software suite for all deep-level interactions.

2. On-Board Display (The Operator's Interface)

The machine's or generator set's main instrument panel is the operator's "control panel." It communicates with the CM871 via J1939 data link to display:

Key Parameters: RPM, temperature, pressure.

Warning and Stop Lamps (Check Engine, Stop Engine).

Sometimes a digital readout for basic fault codes (often called "flash codes").

3. Generic/Third-Party Diagnostic Tools

Many heavy-duty scan tools (e.g., JPRO, Autel, Snap-on) can often connect to the standard J1939/J1587 protocols to read basic fault codes and live data from this ECM.

Critical Technical Notes for CM871 (3684275)

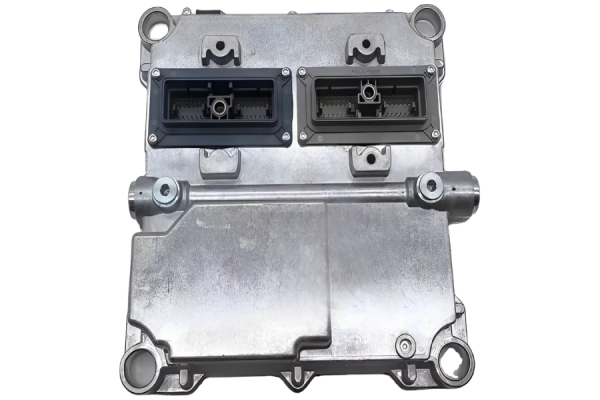

ECM Replacement is NOT Plug-and-Play: If this ECM (S/N 3684275) is replaced, the new ECM is blank. You MUST use INSITE to:

Program the correct engine rating/calibration.

Perform the "ECM Install" procedure.

Input unique engine parameters. Otherwise, the engine will not run correctly.

Communication Failure: If you cannot connect to the ECM, check:

Battery Power & Grounds: The ECM must have clean, stable power (typically unswitched +12V).

Diagnostic Port Wiring: Pins for J1939 Hi/Lo (CAN) and J1587 (if used).

Data Link Adapter: Ensure it's correctly configured for Cummins protocols.

Common Failure Points Beyond the ECM:

Wiring Harnesses: Chafing, corrosion, especially near vibration points.

Sensors: Critical speed/timing (Crankshaft/Camshaft Position Sensors), pressure, and temperature sensors.

Power Supply Relays/Fuses: A faulty relay can cause intermittent ECM shutdown.

Actionable Steps for Diagnostics

Connect INSITE to the diagnostic port.

Read all Fault Codes. Note Active vs. Inactive.

Monitor live data with the engine running to identify anomalies.

Check "ECM Details" in INSITE to verify the calibration number matches the engine application.

Inspect wiring and connectors for integrity if you have intermittent or communication issues.

In summary: The "control panel" for your CM871 ECM is a combination of the equipment's dashboard and, for any technical work, a laptop running Cummins INSITE software.