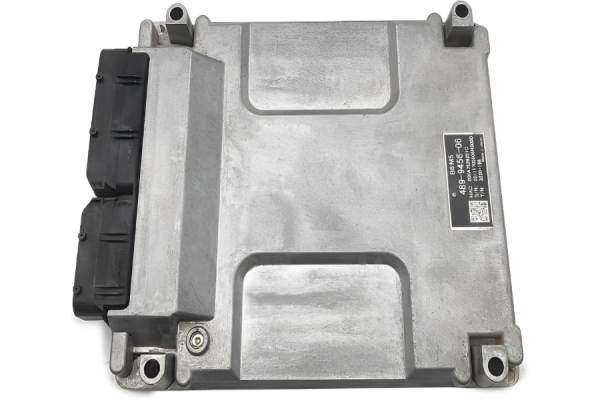

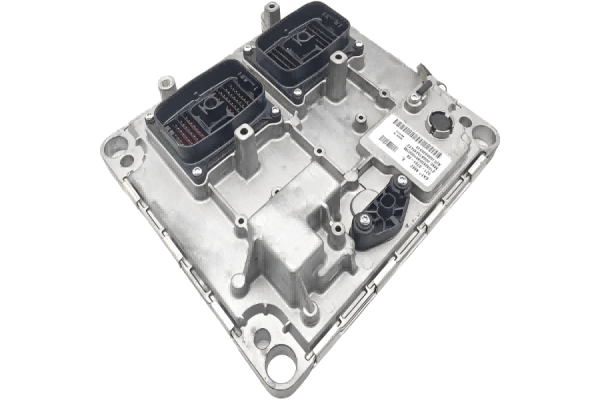

119-0609 1190609 Genuine Second Hand Controller Panel for Caterpillar 320L 312 325

The replacement of the original ECM must strictly follow the Caterpillar repair specifications,

otherwise it may damage the engine:

1. Backup the original ECM parameters

-Using Cat ® ET (Electronic Technician) prints configuration parameters

and records the injector serial number and calibration code (must be reprogrammed

after replacing the injector or ECM).

2. Copy the configuration to the new ECM

-Select 'Copy Configuration/ECM Replacement' → 'Load from ECM' → 'Program ECM' through ET. If it fails,

manual input of parameters is required (some parameters need to be obtained from the factory).

3. Precautions for Hardware Replacement

-Disconnect the power supply and J1/P1, J2/P2 connectors;

-Ensure that the grounding strap is securely installed to avoid poor

contact caused by vibration;

-The fuel pipeline needs to reserve buffer space to prevent pulling the ECM.

4. Software and Calibration

-Install the latest flash file (version errors can cause engine damage);

-Calibrate the fuel injection timing and check for diagnostic codes (such as CID 0600 hydraulic oil

temperature sensor abnormality).

---

4、 Usage and maintenance suggestions

1. Regular diagnosis

-Using Cat ® ET or Messenger reads the fault code (such as CID 0246 CAN

bus abnormality for MID 082) and promptly cleans the sensor dirt.

2. Environmental and oil requirements

-Use clean diesel with a filtration accuracy of ≤ 5 μ m to prevent clogging of precision components;

-The working temperature should be ≤ 26 ℃ to avoid ECM component aging caused by high temperature.

3. Preventive maintenance

-Calibrate rail pressure sensors and flow meters every six months;

-Check the waterproof sealing of the wiring harness, especially in high humidity environments

such as mines and ships.

4. Fault response

-Symptoms of ECM failure: sudden power drop, shaking and stalling, black smoke emission.

-Emergency plan: Immediately shut down the machine, check the power supply and grounding;