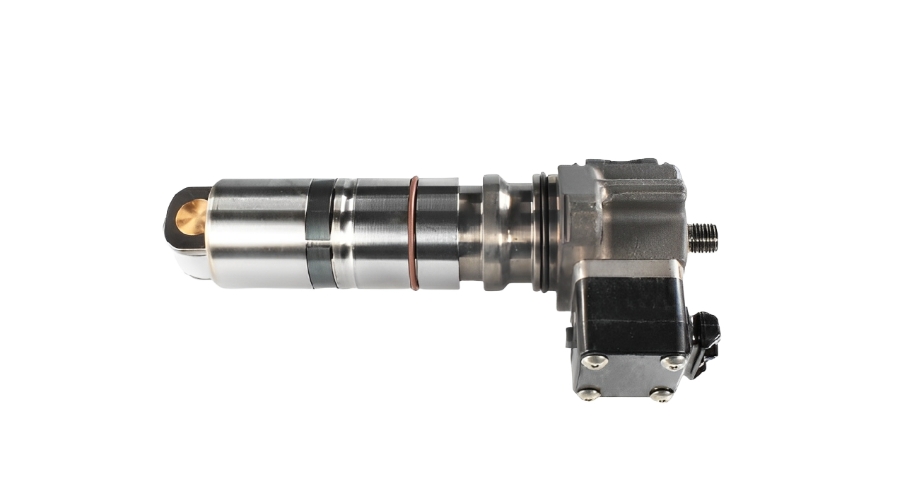

The unit pump is a mechanically actuated, high-pressure fuel pump that works with the engine's electronic control system (ECU) to deliver precise fuel amounts to each cylinder.

a. Housing & Material Construction

Material: Typically made from high-strength alloy steel or forged steel to withstand extreme pressures (up to 1,800–2,200 bar in some systems).

Precision Machining: Critical surfaces (e.g., plunger bore, cam follower) are hardened and ground for durability and smooth operation.

Sealing: Uses high-pressure O-rings and gaskets to prevent fuel leaks.

b. Internal Components

Plunger & Barrel Assembly:

Solenoid Valve (if electronically controlled):

Return Spring:

c. Fuel Inlet/Outlet Ports

Low-pressure inlet: Receives fuel from the supply pump.

High-pressure outlet: Delivers fuel to the injector via a high-pressure line.

2. Strengths & Advantages

The MBE900 unit pump is designed for reliability, efficiency, and performance in heavy-duty applications.

a. High Durability

Robust construction resists wear from continuous high-pressure operation.

Hardened components (e.g., cam follower, plunger) extend service life.

b. Precision Fuel Delivery

Mechanical/electronic control ensures accurate metering for optimal combustion.

Consistent pressure output improves engine efficiency and reduces emissions.

c. Simplified Maintenance

Modular design allows individual replacement (unlike unit injectors, which are more integrated).

Easier troubleshooting compared to common-rail systems in some cases.

d. Compatibility & Adaptability

Works with different MBE900 variants (e.g., 4.8L, 7.2L, 8.3L).

Used in Mercedes-Benz, Freightliner, and Detroit Diesel applications.