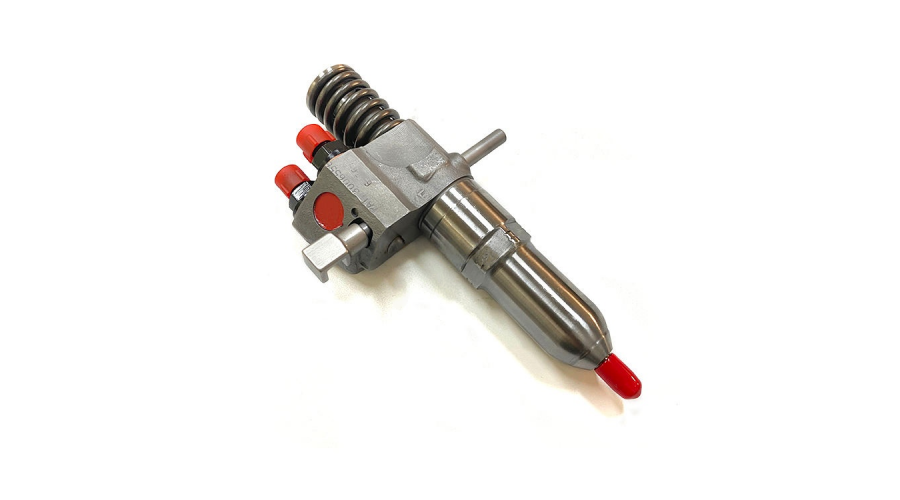

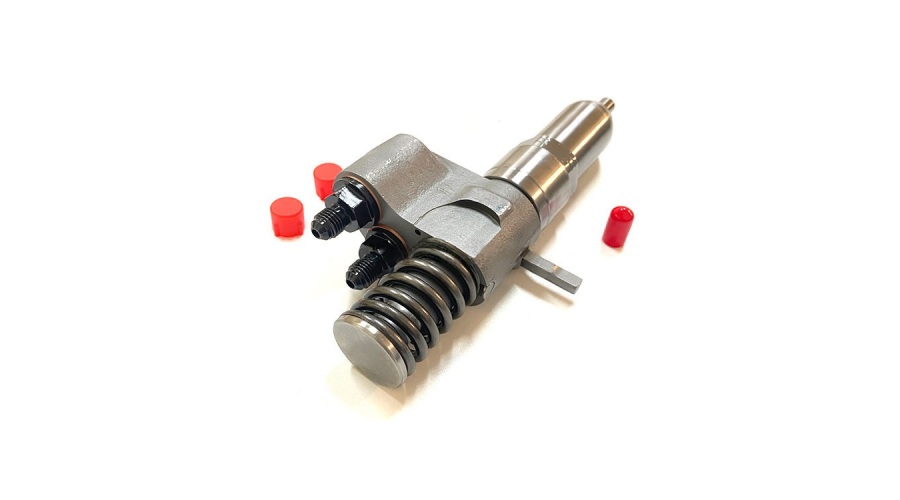

The part number R5235905 is a genuine Detroit Diesel (Daimler Trucks North America - DTNA) remanufactured fuel injector designed for their Series 60 (DDC S60) and DD13/15/16 engines equipped with Common Rail fuel systems.

Here is a detailed breakdown of its application, specifications, and important usage notes:

Primary Application & Engine Compatibility

This injector is used in heavy-duty Detroit Diesel Common Rail engines. Key applications include:

Detroit Diesel Series 60 (S60) – Common Rail Models:

Specifically for the late-model S60 (2007-2011) with the Common Rail system (often referred to as the "E3" or "Blue" engine). It is NOT for the older mechanical or DDEC III/IV unit injector S60 engines.

Typical Horsepower Ratings: 425 hp, 455 hp, 515 hp.

Common in: Freightliner, Western Star, and other OEM trucks from that era.

Detroit Diesel DD13, DD15, and DD16 Engines:

This is the primary injector for these modern GHG2010+ engines.

Used across all power ratings and vocational applications for these platforms.

Found in Freightliner Cascadia, Western Star 5700, and other models from approximately 2010 onward.

1. Structural Characteristics & Technical Advantages

Structural Characteristics:

Quick-Response Solenoid (QRS): Uses a high-speed, direct-acting solenoid valve for precise electronic control, replacing slower piezoelectric or older solenoid designs.

Multi-Hole Nozzle: Precision-machined nozzle with multiple microscopic holes for optimal fuel atomization.

Integrated Design: Combines the solenoid actuator, precision valve, and nozzle into a single, compact unit. Contains internal oil and fuel passages.

Calibration Code Chip: Each injector has a unique factory-measured compensation code for flow and timing, stored on an external label (not an internal chip).

Technical Advantages:

Extreme Precision & Speed: Allows for multiple injection events per cycle (pilot, main, post) for cleaner combustion, reduced noise, and improved efficiency.

High Pressure Operation: Works with common rail systems sustaining pressures up to 2,500+ bar (36,000+ psi), enabling better fuel atomization.

Individual Cylinder Control: The ECM can tailor timing and duration for each injector individually, optimizing performance and compensating for wear.

Improved Emissions & Fuel Economy: The precision of the common rail/QRS system is fundamental to meeting EPA GHG2010 and subsequent emissions standards while maintaining drivability.

2. Main Application Scenarios & Equipment

3. OEM Cross-Reference Number

Primary OEM Remanufactured Number: R5235905 (This is the "R" reman number you asked about).

OEM New Injector Number: 5235905 (This is the base part number for a brand-new unit from Detroit Diesel).

Bosch OEM Core Number: R043ZR0106. Bosch is the original manufacturer of this injector for Detroit Diesel. This is the most critical cross-reference.

(Important: Always verify the exact application by Engine Serial Number (ESN) with your supplier, as minor design revisions exist.)

4. Daily Maintenance & Installation Suggestions

Daily/Maintenance Tips:

Fuel Quality is Critical: Use ultra-low sulfur diesel (ULSD) from reputable sources. Consistently change fuel filters at OEM-specified intervals. Water in fuel is a major injector killer.

Regular ECM Health Checks: Use diagnostic software to monitor injector balance rates/trim codes. Significant deviations between cylinders can indicate a failing injector.

Listen and Observe: Note any hard starting, excessive white/black smoke, loss of power, or increased fuel consumption—these can be early signs of injector issues.

Installation Suggestions (CRITICAL):

Get the Code First: Before touching the old injector, record the new injector's 4-character compensation code from its label.

Impeccable Cleanliness: Clean the valve cover and injector bore area meticulously. Dirt entering the high-pressure system causes rapid failure.

Use New Seals: Always install new OEM copper crush washers and O-rings. Never reuse old ones.

Follow Torque Specs: Use a calibrated torque wrench. Follow the manufacturer's multi-step torque sequence (e.g., first pass, second pass, final angle torque) exactly. This is crucial for sealing the high-pressure fuel and combustion gases.

Programming is Mandatory: You MUST program the new injector's compensation code into the truck's ECM using Detroit Diesel Diagnostic Link (DDDL) or an equivalent professional tool. Skipping this step will cause poor performance and fault codes.

Return the Core: After installation, promptly clean and return your old injector (the "core") to reclaim your core charge.

Fuel Injector Supplier:

Rsolid is a professional diesel fuel injector manufacturer provides high quality and durable diesel fuel injector replacements for different brands of engines or produce fuel injector according to your request. The company is positioned as a specialized and excellent supplier in the foreign trade of automotive components, including high-quality fuel injectors. With years of experience in the international market, Rsolid has established itself as a reliable partner for global clients seeking authentic Detroit products and comprehensive, value-added services. The company operates with a strong commitment to quality assurance, often backed by international certifications common in the automotive parts industry,ensuring that all parts, undergo rigorous testing for flow rate, pressure endurance, and leak integrity before being offered for sale. Rsolid's business model would typically include maintaining a diverse and comprehensive inventory of both OEM and premium aftermarket parts, with cross-compatible options to cater to a wide range of applications and global clientele, from individual workshops to large fleet operators. If you are looking for diesel fuel injector or OEM engine fuel injector, feel free to contact us