The part number 0445010320 is a well-known Bosch high-pressure fuel pump used primarily in Iveco F1C diesel engines.

Here is a comprehensive breakdown of its application, function, common issues, and key details.

Primary Application

This pump is most famously used in the following vehicles and equipment equipped with the Iveco F1C 3.0-liter diesel engine:

Passenger Vehicles:

Fiat Ducato III (from 2006 onwards, especially vans and motorhomes)

Peugeot Boxer / Citroën Jumper (same platform as Ducato)

Alfa Romeo 159 (2.4 JTDM, but note: engine variants differ, verification required)

Commercial Vehicles: Various Iveco Daily vans and trucks with the F1C engine.

Other Applications: Used in some generators and industrial applications with this engine family.

Engine and System Compatibility

Engine: Iveco F1C (3.0L, 4-cylinder).

Injection System: Bosch Common Rail direct injection.

Important Note: While the F1C is the most common application, this pump was also used on some versions of the Fiat 2.3 Multijet (F1A engine) and earlier Fiat 2.8 JTD engines. Always cross-reference with your specific Vehicle Identification Number (VIN) before purchasing, as subtle differences in connectors, pulley sizes, or internal specifications exist.

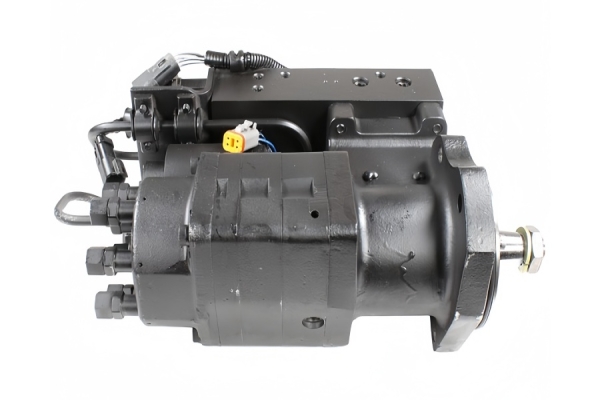

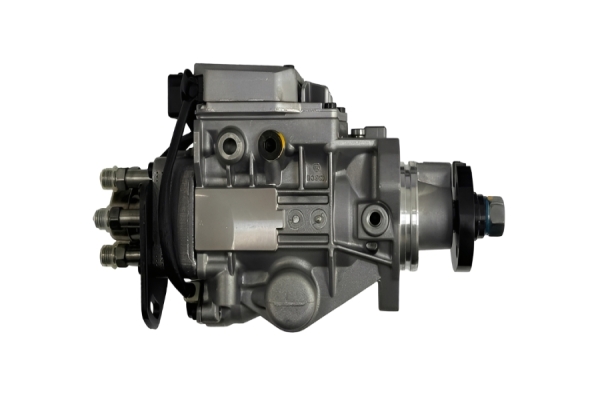

Function of the High-Pressure Pump (CP1 Type)

This Bosch CP1 series pump is the heart of the common rail system:

It is driven by the engine's timing belt (critical for precise timing).

It takes low-pressure fuel (supplied by the in-tank lift pump) and pressurizes it to extremely high levels (up to 1600 bar or more).

It delivers this high-pressure fuel to the common rail, a shared accumulator, which then supplies the injectors.

It features a fuel quantity solenoid valve (also called a metering unit or M-PROP) controlled by the Engine Control Unit (ECU) to regulate the exact amount of fuel entering the high-pressure stage for optimal efficiency and pressure control.

Common Issues & Symptoms of Failure

Failure of this pump is a known issue and can be costly due to potential collateral damage.

Internal Wear: The main cause of failure. The plungers and barrel wear out, leading to:

Loss of high-pressure fuel delivery.

Hard starting or no-start conditions, especially when hot.

Lack of power, limp mode, and excessive black smoke.

Trouble codes like P0190, P0191, P0192, P0193 (fuel rail pressure sensor/control range/performance).

Contamination Failure (Most Serious): If the pump's internal components begin to disintegrate, or if contaminated fuel enters, it sends metal shavings throughout the entire fuel system.

This contaminates the common rail and fuel injectors. A pump replacement must be accompanied by flushing or replacing the rail and injectors, and cleaning the fuel tank/lines. A complete repair kit is often necessary.

Solenoid Valve Failure: The fuel metering valve (on the side of the pump) can fail electrically or become clogged.

Here are the main advantages of the Bosch CP1 high-pressure pump (0445010320) in a nutshell:

1. Precision & High Pressure: Enables ultra-fine, efficient fuel atomization in the common rail system, leading to better combustion, more power, lower emissions, and improved fuel economy.

2. Integrated Control: Its fuel metering solenoid valve (M-PROP) allows the engine ECU to precisely control fuel volume on demand. This optimizes performance and efficiency across all engine speeds.

3. Compact & Robust Design: As a radial piston pump (3 pistons), it is smaller and lighter than older inline pumps, yet durable enough for demanding commercial vehicle use.

4. System Efficiency: By generating pressure independently of engine speed, it maintains optimal rail pressure for clean injection events even at low RPM, reducing noise and smoke.