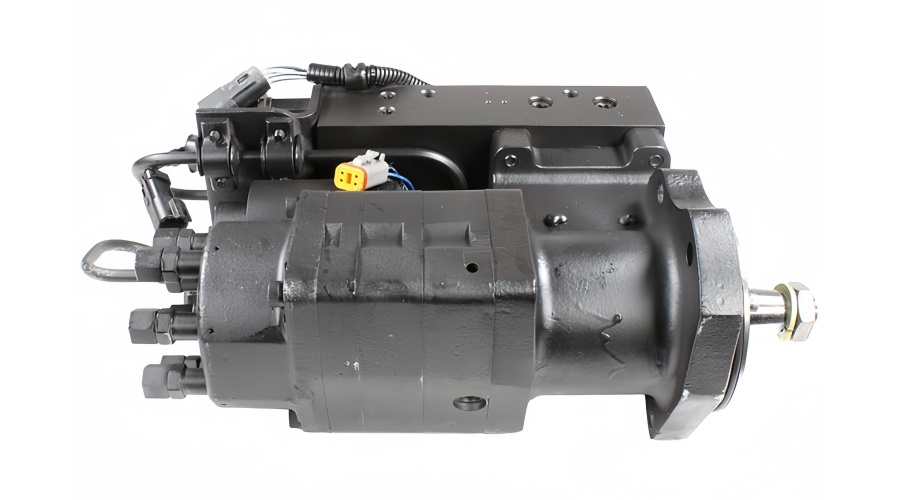

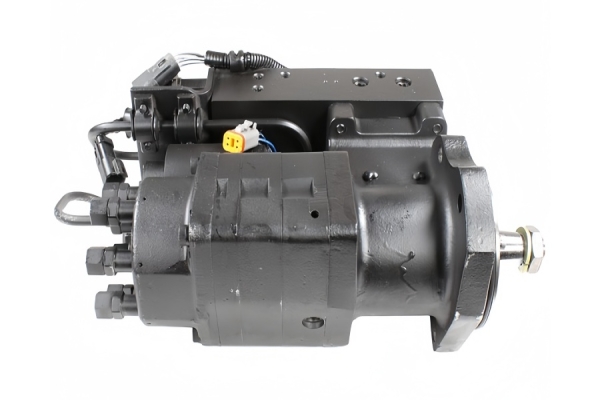

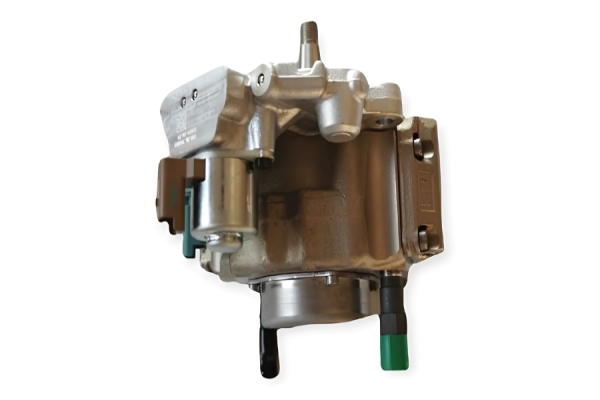

| Pump Type | Electronically Controlled Rotary Distributor Pump | "Unit Pump System" precursor. Has an internal ECU. |

| Common Applications | Cummins 6BT5.9, 6CT8.3, ISB 5.9L (early) | Also used in some V8 and inline-6 applications from other manufacturers. |

| Number of Outlets | Typically 6 (for inline-6 engines) | Distributes high-pressure fuel sequentially to each cylinder. |

| Maximum Injection Pressure | ~1600 - 1800 bar (23,200 - 26,100 psi) | A key performance spec. Drops indicate internal wear. |

| Transfer Pump Type | Internal Vane Pump (supply pump) | Creates low-pressure feed (~5-8 bar) for the high-pressure stage. Prone to wear from poor fuel. |

| Electrical Control | Internal Mounted ECU (Electronic Control Unit) | Receives signals from engine sensors. Controls solenoid valves for timing and quantity. A common failure point. |

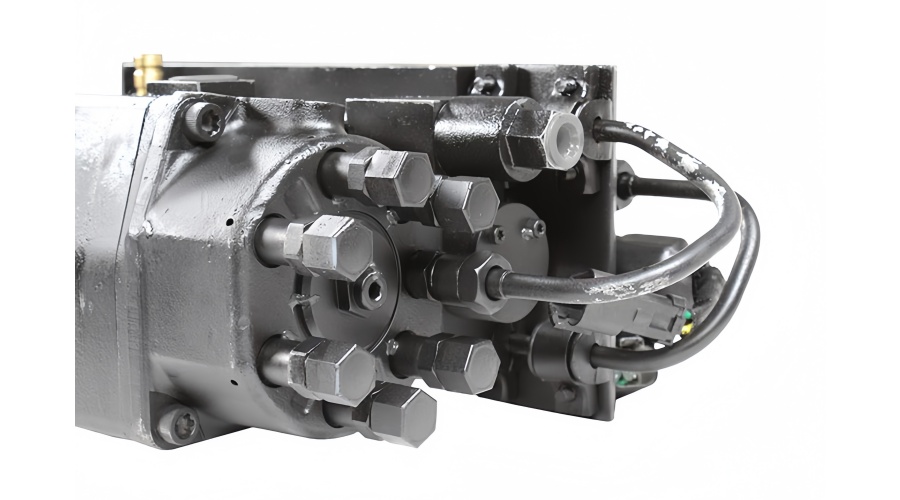

| Control Solenoids | • Injection Quantity Solenoid (Metering Valve)

• Timing Control Solenoid | Adjusts fuel volume and advance based on ECU commands. |

| Fuel Lubrication | Fuel is the lubricant for internal components. | Makes fuel quality and lubricity absolutely critical. |

| Key Wear Components | 1. Rotor & Roller Head Assembly

2. Cam Ring

3. Transfer Pump Vanes & Ring

4. Pressure Control Valve (PCV) | These are the mandatory replacement items during high-quality remanufacturing. |

| Critical Clearance | Rotor-to-Head Clearance | Measured in microns. Excessive clearance is the primary cause of low high-pressure output. |