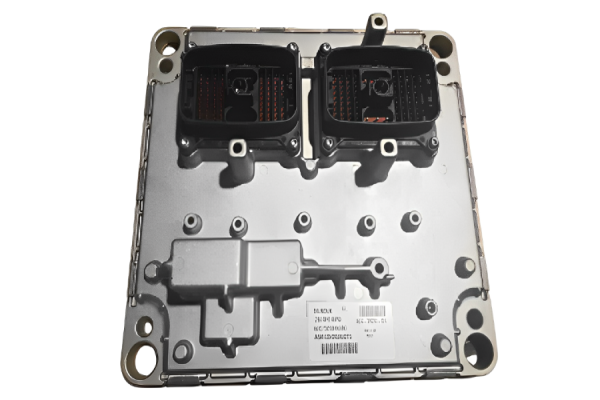

The Caterpillar ECM part number 462-0007 (also sometimes labeled as 322-6207 or 322-6207NA) is primarily used for the C7.1 Industrial Engine, which powers several Caterpillar machines. Below are some of the common models that may use this ECM:

Equipment Models Using the 462-0007 ECM (C7.1 Engine):

Wheel Loaders:

CAT 906M, 907M, 908M (Compact Wheel Loaders)

CAT 924K, 930K, 938M, 950M, 962M, 966M, 972M, 980M, 982M (Medium/Large Wheel Loaders)

CAT 960F (Older model, may depend on engine serial number)

Excavators:

CAT 301.5, 301.7, 301.8 (Mini Excavators)

CAT 303, 303.5, 304, 305, 305.5, 307, 308, 309, 310 (Small-Medium Excavators)

Backhoe Loaders:

Skid Steers & Compact Track Loaders:

CAT 246D, 247D, 248D, 249D, 252D, 257D, 259D, 262D, 272D, 277D, 279D

Other Equipment:

CAT AP655F, AP1000F (Asphalt Pavers)

CB64B, CB66B (Vibratory Compactors)

D6K2, D6XE (Dozer – if equipped with C7.1)

TH514, TH522, TH535 (Telehandlers)

Important Notes:

Engine Serial Number (ESN) Matters:

The exact ECM compatibility depends on the engine serial number (not just the machine model).

Some machines may have different ECMs based on emissions tier (Tier 4 Final, Stage V, etc.).

Cross-Reference Part Numbers:

322-6207 (OEM equivalent)

322-6207NA (North America variant)

Aftermarket ECMs may use different numbers.

Reprogramming May Be Required:

Next Steps:

4、 Usage and maintenance suggestions

1. Regular diagnosis

-Using Cat ® ET or Messenger reads the fault code (such as CID 0246 CAN

bus abnormality for MID 082) and promptly cleans the sensor dirt.

2. Environmental and oil requirements

-Use clean diesel with a filtration accuracy of ≤ 5 μ m to prevent clogging of precision components;

-The working temperature should be ≤ 26 ℃ to avoid ECM component aging caused by high temperature.

3. Preventive maintenance

-Calibrate rail pressure sensors and flow meters every six months;

-Check the waterproof sealing of the wiring harness, especially in high humidity environments

such as mines and ships.

4. Fault response

-Symptoms of ECM failure: sudden power drop, shaking and stalling, black smoke emission.

-Emergency plan: Immediately shut down the machine, check the power supply and grounding;