Primary Engine Applications:

The R-5228900 injector is used in the Series 60 and Series 50 engines, which are the backbone of the North American heavy-duty trucking industry for decades.

Series 60 (12.7L & 14L): This is the most common application. It was used in countless Freightliner, Western Star, Kenworth, Peterbilt, and Volvo trucks.

Series 50 (12.7L): The urban bus and vocational truck engine. It's essentially a vertical version of the Series 60 and uses the same injector

1. Structural Characteristics & Technical Advantages

Structural Characteristics:

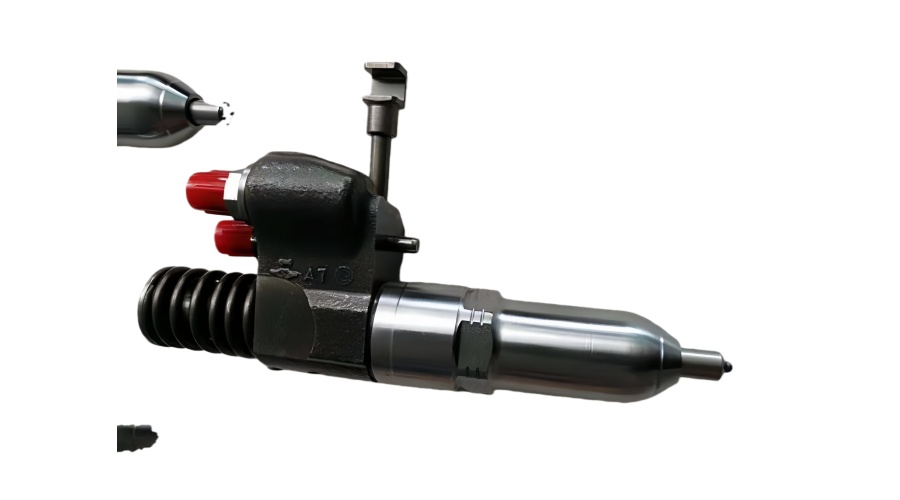

This is an Electronic Unit Injector (EUI), a highly integrated, cam-driven design.

Single Unit Design: It combines a high-pressure fuel pump and an electronically controlled injector nozzle into one compact unit. It is installed directly into the cylinder head.

Cam-Driven: A lobe on the engine's camshaft actuates a rocker arm, which pushes down on the injector's plunger to generate extremely high injection pressure (upwards of 30,000 psi).

Solenoid Controlled: An integrated solenoid valve, commanded by the engine's ECM (DDEC), precisely controls the timing and duration of fuel injection.

Internal Fuel Circuit: Fuel enters the injector, serves as both a lubricant/coolant for the plunger and barrel, and is then metered for injection. Excess fuel returns to the tank.

Technical Advantages:

Extremely High Injection Pressure: Cam-driven mechanics allow for consistently higher pressure than many common-rail systems of its era, resulting in superior fuel atomization, cleaner burning, and better fuel efficiency.

Precision and Responsiveness: Direct electronic control over each injector enables highly precise timing for optimal power, low emissions, and smooth operation.

Reliability & Simplicity: It eliminates the need for a separate high-pressure fuel pump and complex external lines, reducing potential leak points. Its mechanical actuation is robust.

Self-Contained: Each injector operates independently; a failure of one does not cripple the entire high-pressure fuel system.

2. Main Application Scenarios & Equipment

This injector was the heart of Detroit Diesel's flagship engines for over-the-road and vocational applications from the late 1980s through the 2000s.

Primary Application: Heavy-Duty Line-Haul Trucks. It was the standard in North American freight transportation for two decades.

Truck Brands: Freightliner (Classic, Century, Columbia), Peterbilt, Kenworth, Western Star, Volvo, Mack (with Detroit engines).

Vocational & Industrial Equipment: Dump trucks, loggers, refuse trucks, fire trucks, and stationary power generation units.

Public Transit: Urban Transit Buses powered by the Series 50 engine.

Engines:

3. OEM Cross-Reference Part Numbers

The R-5228900 is Detroit's remanufactured service part number. Key cross-references include:

Detroit Diesel New/Other Numbers:

5228900 (Likely the original new part number)

R-5228900 (Standard remanufactured part)

R-5228900AX (Often denotes a premium or extended warranty reman)

Major OE Supplier Numbers: These companies supplied injectors or components to Detroit Diesel.

Common Aftermarket/Interchange Numbers:

Important Note: Always verify the orifice size (710) and confirm the calibration codes match your engine's requirements before purchasing. The Bosch number is the most universally recognized alternate.

4. Daily Maintenance Suggestions

For EUIs, "daily maintenance" is about prevention and monitoring. You don't service the injector itself daily, but you protect it.

Fuel Quality is Paramount: Use only high-quality, clean, on-road ultra-low sulfur diesel (ULSD). The tolerances inside an EUI are measured in microns. Contaminated fuel is the #1 cause of failure.

Aggressive Fuel Filter Maintenance:

Change both primary and secondary fuel filters at the OEM-recommended intervals (typically every 15,000-30,000 miles). Never extend intervals.

Use only premium, branded filters (e.g., Fleetguard, Donaldson, Baldwin). The fuel filter/water separator is the injector's only protection.

Water Draining: Drain water from the fuel filter/water separator daily or as part of every pre-trip inspection. Water destroys the lubricity of fuel and causes rapid corrosion and wear in the injector.

Air Management: Ensure the air intake system is sealed and the filter is serviced. Excess dirt can lead to poor combustion and soot buildup.

Operational Monitoring:

Listen: Be alert for a change in engine sound—a "miss," a "knock," or excessive clicking from the valve cover.

Watch: Monitor for excessive black/white smoke, hard starting, loss of power, or a sudden increase in fuel consumption.

Check: Periodically check for fuel leaks around the injector base or the return line fittings.

Use the Correct Engine Oil: Use only the recommended API-classified diesel engine oil (e.g., CJ-4, CK-4). Oil can enter the fuel system via the injector's O-rings and affect lubrication.

When Service is Needed: Injector replacement is a professional job. It requires reading/recording calibration codes, specialized tools for removal/installation, precise torque procedures, and mandatory ECM reprogramming with the new injector's codes. Never attempt this without the proper tools and software.

Fuel Injector Supplier:

Rsolid is a professional diesel fuel injector manufacturer provides high quality and durable diesel fuel injector replacements for different brands of engines or produce fuel injector according to your request. The company is positioned as a specialized and excellent supplier in the foreign trade of automotive components, including high-quality fuel injectors. With years of experience in the international market, Rsolid has established itself as a reliable partner for global clients seeking authentic Denso products and comprehensive, value-added services. The company operates with a strong commitment to quality assurance, often backed by international certifications common in the automotive parts industry,ensuring that all parts, undergo rigorous testing for flow rate, pressure endurance, and leak integrity before being offered for sale. Rsolid's business model would typically include maintaining a diverse and comprehensive inventory of both OEM and premium aftermarket parts, with cross-compatible options to cater to a wide range of applications and global clientele, from individual workshops to large fleet operators. If you are looking for diesel fuel injector or OEM engine fuel injector, feel free to contact us.