What are the classifications and main differences of fuel injectors ?

Here is a detailed breakdown of engine injector types, categorized by their most common distinctions.

1. By Fuel Type

This is the primary division, as diesel and gasoline have fundamentally different ignition properties.

A. Diesel Injectors

Diesel fuel is injected into highly compressed, hot air, where it ignites spontaneously (compression ignition). Injectors must withstand extremely high pressures.

Function: Deliver precise amounts of fuel and actively aid in atomization.

Key Technology: High Pressure Common Rail (HPCR) system is now standard. A high-pressure pump supplies fuel to a common "rail" (manifold), and each injector is fed from this rail, allowing for extremely precise, computer-controlled injection events.

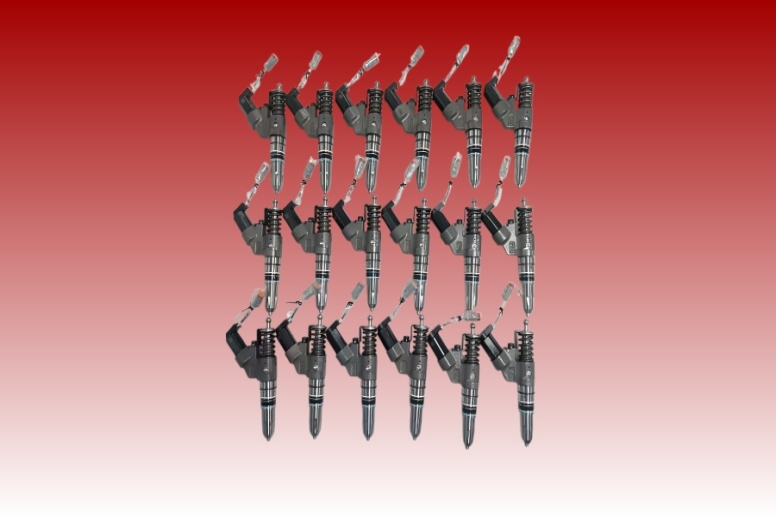

Types of Diesel Injectors:

Mechanical Injectors: Older technology. Use fuel pressure and springs to open/close. Limited precision (e.g., in-line pump systems).

Electronic (Solenoid) Injectors: Modern standard. An electronic solenoid controls the needle valve, allowing for multiple injection events per cycle (pilot, main, post) for power, noise reduction, and emissions control.

Piezoelectric Injectors: The most advanced. Use piezoelectric crystals that expand with electricity almost instantly (faster than solenoids). Enable even more precise, faster, and multiple injections per cycle for ultimate efficiency and lower emissions.

B. Gasoline (Petrol) Injectors

Gasoline is typically mixed with air before entering the cylinder and ignited by a spark plug (spark ignition). Pressures are much lower than diesel.

Function: Deliver a finely atomized spray of fuel into the air stream.

Key Technology: Electronic Fuel Injection (EFI). The Engine Control Unit (ECU) pulses the injector open for a precise duration based on engine load.

2. By Mounting Location (Gasoline Engines)

This refers to where the injector sprays the fuel.

Throttle Body Injector (TBI): A single or dual injector mounted in the throttle body (above the throttle butterfly). Sprays fuel into the incoming air, similar to a carburetor. Simple, older technology, less precise.

Port Fuel Injector (PFI) or Multi-Point Fuel Injector (MPFI): The standard for decades. One injector per cylinder mounted in the intake port, just before the intake valve. Provides good atomization and cylinder-to-cylinder fuel control.

Direct Injection (GDI / DI): The modern high-performance/efficiency standard. The injector is mounted directly into the combustion chamber, like a diesel injector. Allows for precise control over the air-fuel mixture, enabling higher compression ratios and improved thermal efficiency. More complex and prone to carbon buildup on intake valves.

3. By Actuation Method (How They Open/Close)

Solenoid-Type: The most common type. An electromagnetic solenoid is energized by the ECU, pulling the injector needle open. Used in virtually all modern gasoline systems and many diesel systems.

Piezoelectric-Type: As mentioned for diesel, uses super-fast piezoelectric crystals. Found in top-tier diesel engines (and some experimental gasoline systems) for ultimate precision.

Mechanical (Pressure-Actuated): Found in older diesel engines. Fuel pressure from the injection pump itself overcomes a spring to open the injector.

4. By Nozzle Design & Spray Pattern

The tip design is critical for proper atomization and mixing.

Hole-Type Nozzle (Multi-Hole): Common in direct injection (both diesel and GDI). Has multiple tiny holes that create several precise fuel plumes. The number, angle, and size of holes are engineered for specific combustion chamber shapes.

Pintle-Type Nozzle: Older design, often in throttle body or older port injectors. A needle (pintle) protrudes through a ring-shaped orifice, producing a conical spray. Good resistance to carbon fouling.

Disc (Sac) Nozzle: Common in older diesel injectors. Fuel is held in a small chamber ("sac") at the tip before injection. Can lead to fuel dribble.

Valve Covered Orifice (VCO) Nozzle: Modern diesel design. The needle valve seat is at the very tip, eliminating the sac and reducing fuel dribble and emissions.

Comparison Table at a Glance

| Feature | Diesel (HPCR) | Gasoline Port (PFI) | Gasoline Direct (GDI) |

|---|---|---|---|

| Typical Pressure | Very High (1,500 - 3,000+ bar) | Low (3-5 bar) | High (150-350 bar) |

| Location | Directly into combustion chamber | Intake port | Directly into combustion chamber |

| Primary Goal | Control atomization & mixing | Deliver atomized fuel to intake valve | Precise in-cylinder mixture control |

| Key Advantage | Torque, efficiency | Reliability, low cost | Power, fuel efficiency, emissions |

| Key Disadvantage | Cost, complexity, noise (if older) | Less efficient than GDI | Carbon buildup, cost, particulates |

Evolution & Future Trends

Dual Injection/Port+Direct: Some advanced engines (e.g., Toyota, VW) combine both port and direct injectors on the same engine for the best of both worlds: cleanliness and power.

Increased Pressure: Both diesel and GDI systems are moving to even higher pressures for better atomization (finer droplets) and efficiency.

Gasoline Compression Ignition (GCI): An emerging technology using gasoline in a compression-ignition cycle, requiring ultra-precise injectors that blend the capabilities of both diesel and GDI types.