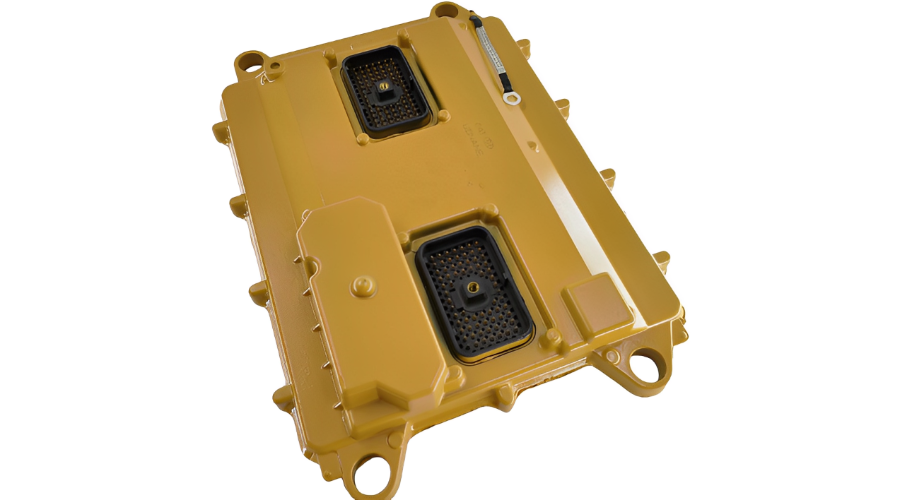

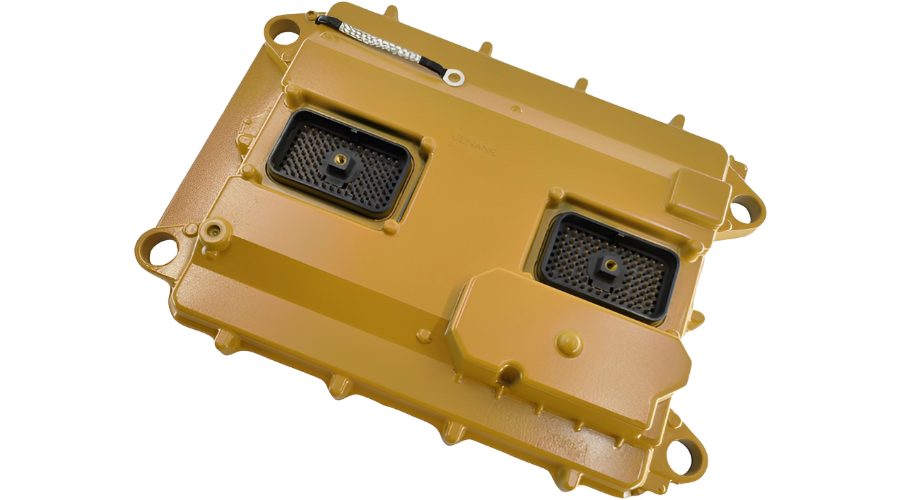

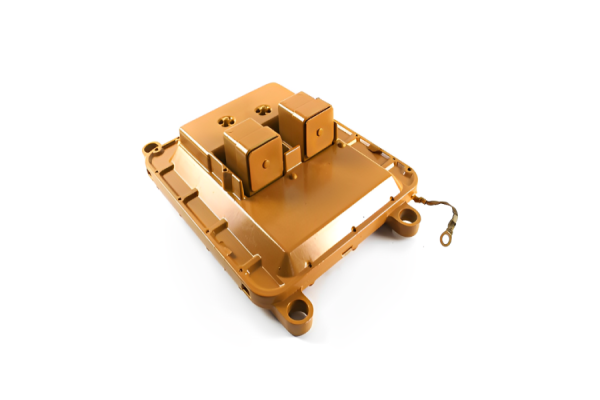

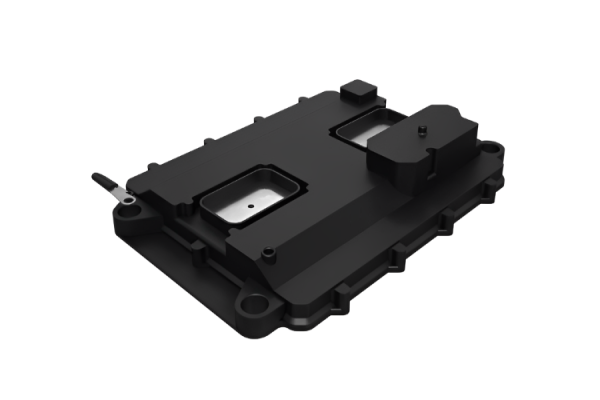

The 348-2377 Engine Electronic Control Module (ECM) is a critical component used in Caterpillar (CAT) engines to manage and regulate engine performance, fuel efficiency, emissions, and other vital functions.

Key Features of the 348-2377 ECM:

Engine Monitoring & Control: Manages fuel injection timing, air-to-fuel ratio, and engine speed.

Fault Diagnostics: Detects and logs error codes for troubleshooting (accessible via CAT ET or other diagnostic tools).

Emissions Compliance: Helps engines meet EPA and other regulatory standards.

Compatibility: Used in various CAT engine models (check specific application before purchase).

Durable Construction: Designed to withstand harsh operating conditions (vibration, temperature extremes).

Common Applications:

CAT Industrial Engines

Heavy Equipment (Excavators, Bulldozers, Loaders)

Power Generation Units

Marine & Off-Highway Engines

Troubleshooting & Maintenance:

If the ECM fails, symptoms may include engine misfires, power loss, or failure to start.

Use CAT Electronic Technician (ET) software for diagnostics.

Ensure proper wiring harness connections before replacing the ECM.

Usage and maintenance suggestions:

1. Regular diagnosis

-Using Cat ® ET or Messenger reads the fault code (such as CID 0246 CAN bus abnormality for MID 082)

and promptly cleans the sensor dirt.

2. Environmental and oil requirements

-Use clean diesel with a filtration accuracy of ≤ 5 μ m to prevent clogging of precision components;

-The working temperature should be ≤ 26 ℃ to avoid ECM component aging caused by high temperature.

3. Preventive maintenance

-Calibrate rail pressure sensors and flow meters every six months;

-Check the waterproof sealing of the wiring harness, especially in high humidity environments such as mines and ships.

4. Fault response

-Symptoms of ECM failure: sudden power drop, shaking and stalling, black smoke emission.

-Emergency plan: Immediately shut down the machine, check the power supply and grounding;